Challenges In Industrial Solar Installations And How To Overcome Them

- December 22, 2025

Rahul Bhosale

Author -

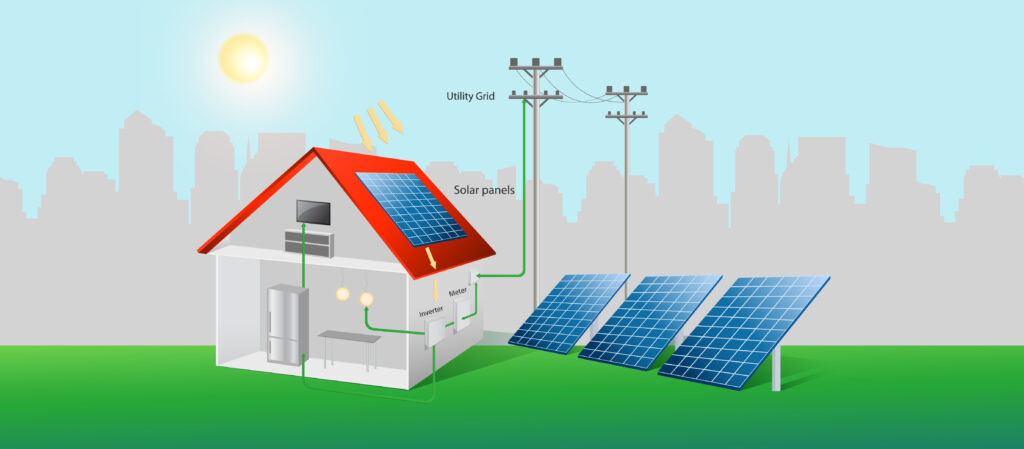

Across manufacturing, warehousing, engineering, and processing facilities, more businesses are turning to solar to cut energy costs and meet sustainability goals. Industrial roofs and nearby land offer a natural space for clean power generation and long term savings.

However, the journey is not always smooth. There are genuine challenges in industrial solar installations that can slow down or even derail a project if they are not handled properly. These range from technical design issues to financial doubts and grid related solar energy problems. The good news is that most of these obstacles can be managed with the right planning and the right partners.

Common Challenges In Industrial Solar Installations

Technical Challenges

One of the main challenges in industrial solar projects is technical complexity. Industrial plants usually have:

- Multiple feeders and complex single line diagrams

- High starting currents from motors and compressors

- Sensitive equipment that needs stable voltage and frequency

Poor system design, wrong inverter sizing, or weak protection schemes can cause nuisance tripping, power quality issues, or lower generation. These technical gaps reduce confidence in solar and make plant teams wary of further expansion.

A detailed site survey, accurate load analysis, and proper coordination with existing electrical infrastructure are essential to avoid these issues.

Space And Structural Limitations

Even when a factory has a large roof, not all of it is usable. Common problems include:

- Old or weak roofing sheets

- Heavy equipment or ducts already placed on the roof

- Shadows from nearby buildings, trees, or chimneys

As several studies point out, structural strength, shading, and roof condition are key concerns for commercial and industrial rooftop solar.

These challenges in industrial solar installations can limit system size and affect expected savings. A proper structural audit and shading analysis help decide where panels can safely sit and what generation is realistic.

Financial And ROI Concerns

Many boards still see solar as a capital heavy decision. Typical questions include:

- What is the real payback period

- How will it affect cash flow and borrowing limits

- What happens if policies or charges change later

Unclear financial modelling and lack of scenario planning create hesitation. This is where an experienced industrial solar installation company and a good finance team must work together to present a simple, clear ROI story.

Issues With Solar Energy And How They Affect Industries

Grid Integration Problems

One of the less visible issues with solar energy at industrial scale is grid integration. Traditional grids were designed for one way flow of electricity, not for large amounts of power coming back from many solar plants. This can create problems such as:

- Voltage fluctuations

- Reverse power flow

- Protection coordination issues

Research on grid integration of solar highlights concerns about power quality, stability, and equipment stress when solar plants are not properly integrated. For an industrial unit, this can mean unexpected trips, downtime, or extra investment in protection and control equipment.

Weather, Efficiency, And Other Solar Energy Problems

Solar generation depends on sunlight. Clouds, dust, high temperatures, and seasonal changes all affect output. Panels can produce only 30 to 50 percent of their optimal capacity on very cloudy days, and high temperature can reduce efficiency further.

These solar energy problems do not mean solar is unreliable, but they must be planned for. If management expects the plant to perform at peak generation every day of the year, they will be disappointed. A realistic energy model, based on local weather and proper loss assumptions, keeps expectations grounded.

Solutions And Best Practices

Choosing The Right EPC Partner

Many of the challenges in industrial solar installations can be prevented at the design and planning stage. This is why choosing the right industrial solar installation company or solar EPC partner is critical.

A strong EPC partner will:

- Conduct a thorough technical and structural assessment

- Study load patterns and coordinate with your electrical team

- Design for safety, maintainability, and future expansion

- Help you choose between rooftop, ground mount, and even group captive solar if roof space is not enough

- Provide clear financial models with payback, IRR, and risk scenarios

Checking references, visiting existing plants, and reviewing monitoring data from operating projects are practical ways to judge an EPC’s capabilities.

Advanced Monitoring And Maintenance

Even the best design will not deliver if the system is not monitored and maintained. Dust, bird droppings, loose connections, and inverter faults can silently reduce output.

Modern monitoring platforms give live data on generation, performance ratio, and equipment health. When combined with a structured maintenance plan, they help solve many ongoing issues with solar energy before they become serious.

Key best practices include:

- Remote monitoring with alerts for underperformance

- Regular cleaning and visual inspection

- Periodic thermography and IV curve testing

- Clear roles through an operations and maintenance contract

This is where a professional EPC that also offers strong O&M services can make a big difference to long term performance.

Conclusion

Industrial solar has moved from being a niche idea to a practical tool for cost control and sustainability. Yes, there are genuine challenges in industrial solar installations, from technical complexity and roof limitations to solar energy problems linked to weather and grid integration. However, each of these can be addressed with the right data, the right design, and the right partners.

If your organisation is exploring solar, work with a capable industrial solar installation company that understands your process, your loads, and your risk profile like Aara Energy. Ask for clear engineering reasoning, realistic financials, and a long term plan for monitoring and maintenance.

The sooner these challenges are understood and addressed, the sooner your plant can start benefiting from clean, reliable, and cost effective solar power.

Related Blogs